Phosphorus Bronze

Phosphorus Bronze also called as Phos Bronze is an alloy of copper with 3.5 to 10% of tin and a significant Phosphorus content of up to 1%. The tin content in this Alloy increases the corrosion resistance and strength of the alloy itself. Phosphorus Bronze provided by Mallinath Metal has excellent formidability and superiority compared to other players. They have multiple applications like, sleeve bearings, thrust washers, etc.

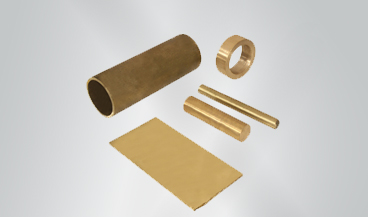

Phosphorus Bronze alloys are primarily used for electrical products because they have superb spring qualities, high fatigue resistance, excellent formability, and high corrosion resistance. The addition of tin increases the corrosion resistance and strength of the alloy. The Phosphor increases the wear resistance and stiffness of the alloy. Phosphorus Bronze C544 is one of the finest bearing alloys the industry has to offer. Phosphorus Bronze is available in sheet, strip, plate, wire, rod and bar.

Applications of Phosphorus Bronze:

Chemical Composition :

| Component | Wt. % |

| Cu | 90.5 – 92.8 |

| Fe | Max 0.1 |

| P | 0.03 – 0.35 |

| Pb | Max 0.05 |

| Sn | 7 – 9 |

| Zn | Max 0.2 |

Physical Properties :

| Density ( g cm-3 ) | 8.9 |

| Melting point ( C ) | 900-1050 |

Mechanical Properties :

| Elongation at break ( % ) | <60 |

| Hardness - Brinell | 80-225 |

| Izod impact strength ( J m-1 ) | 62 |

| Modulus of elasticity ( GPa ) | 90-120 |

| Shear strength ( MPa ) | 250-430 |

| Tensile strength ( MPa ) | 320-740 |